Alpha HPA’s Stage Two FID: A Game Changer for Alpha Sapphire

20 May 2024

Natural Sapphire vs. Synthetic Sapphire

2 July 2024

Alpha HPA’s Stage Two FID: A Game Changer for Alpha Sapphire

20 May 2024

Natural Sapphire vs. Synthetic Sapphire

2 July 2024The perfect feedstock for synthetic sapphire growth.

2 July 2024 – ⏱ 5 min Read

The Perfect Feedstock for Synthetic Sapphire Growth

In the world of high-tech materials, the purity of raw materials significantly impacts the quality and performance of the final product. Alpha HPA, a leading innovator in aluminium purification, provides ultra-high purity aluminium oxide pellets and pucks that serve as the feedstock for Alpha Sapphire’s synthetic sapphire production. Here’s an in-depth look at what makes Alpha HPA’s aluminium oxide the ideal choice for synthetic sapphire manufacturing.

Ultra-High Purity (4N5+% Purity)

Alpha HPA’s aluminium oxide boasts an impressive purity level of 4N5+% (99.995+%), ensuring minimal impurities and ultimate performance. This ultra-high purity is critical for producing synthetic sapphire with superior optical clarity and structural integrity. High purity reduces the likelihood of defects and enhances the performance of the synthetic sapphire in demanding applications.

Ultra Low Carbon

The Smart SX technology employed by Alpha HPA ensures that their aluminium oxide products have ultra-low carbon content. This advanced purification process uses solvent extraction to selectively remove impurities with pinpoint accuracy. The result is an environmentally friendly process that significantly lowers total carbon emissions compared to traditional methods, aligning with global sustainability goals.

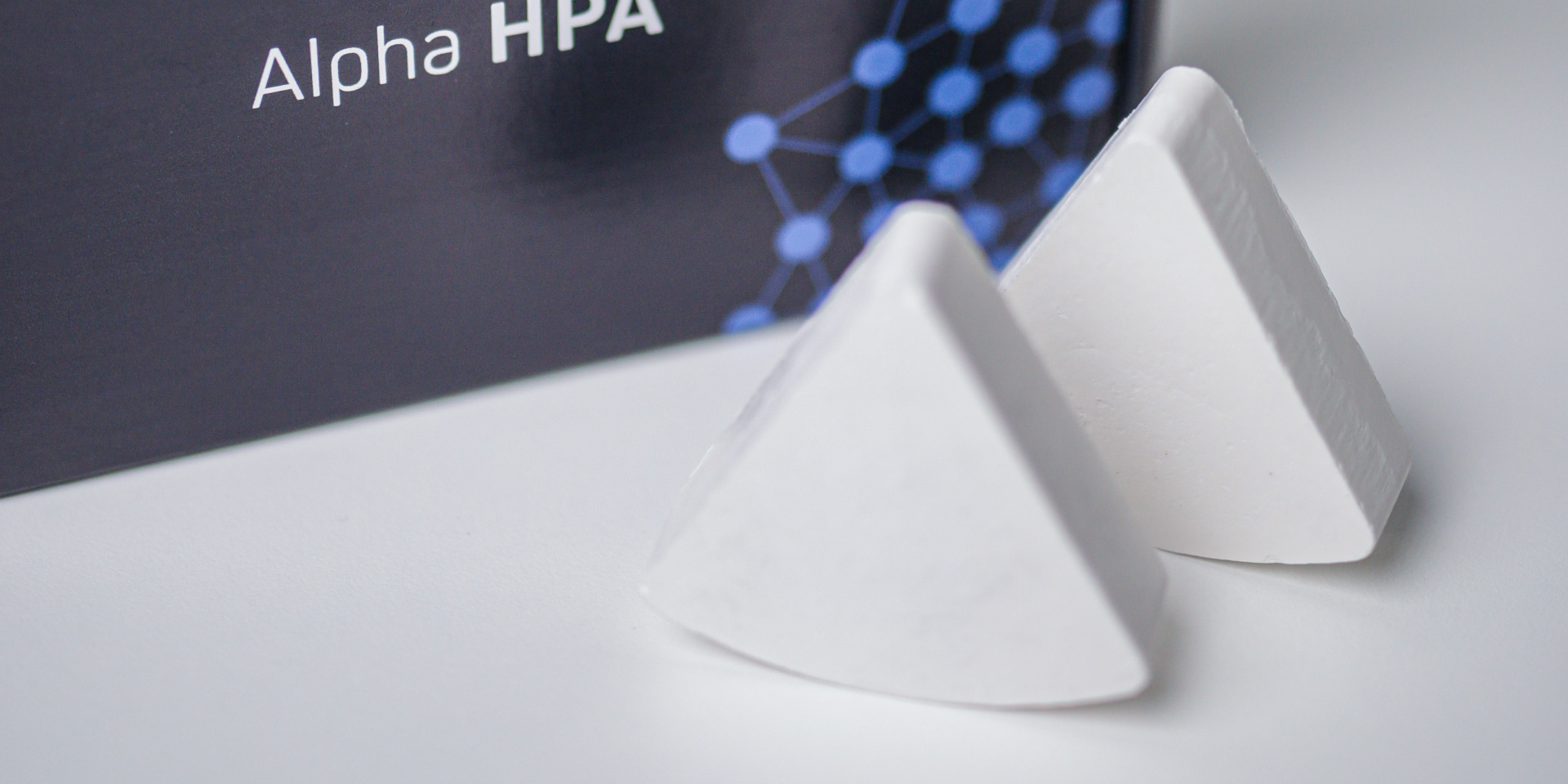

Versatility in Sizes and Shapes

Alpha HPA’s aluminium oxide feedstock is available in a variety of sizes and shapes, including tablets, pellets, and discs. This versatility allows manufacturers like Alpha Sapphire to optimize their production processes. Customizable shapes such as square, “pizza” shape, and standard discs provide flexibility in the manufacturing workflow, enhancing efficiency and reducing waste.

Applications and Benefits

The ultra-high purity and customizable form factors of Alpha HPA’s aluminium oxide make it an excellent feedstock for producing synthetic sapphire. Here’s how it benefits various applications:

- Optical Components: Ensures high transparency and minimal defects in lenses, prisms, and other optical elements.

- LED Substrates: Provides a high-quality surface for epitaxial growth, crucial for high-efficiency LEDs.

- Aerospace and defence: Enhances the durability and performance of optical windows and sensor covers.

- Consumer Electronics: Improves the scratch resistance and clarity of screens and camera lenses.

- Industrial Uses: Supports high-power lasers and advanced manufacturing technologies with reliable and durable components.

Conclusion

Alpha HPA’s high purity aluminium oxide is a vital component in the production of Alpha Sapphire’s synthetic sapphire. The exceptional purity, low carbon content, and versatility in form factors ensure that Alpha Sapphire can produce top-quality synthetic sapphire for a wide range of high-tech applications. By leveraging Alpha HPA’s innovative Smart SX technology, the production process is not only efficient but also environmentally sustainable, paving the way for a greener future in advanced materials manufacturing.

For more information on Alpha HPA’s revolutionary aluminium purification technology, contact our Sales Marketing Manager, Derek Bogaert, at hello@alphasapphire.com